Deburring Tool Holder

“Super Finish” Air Float Attachment

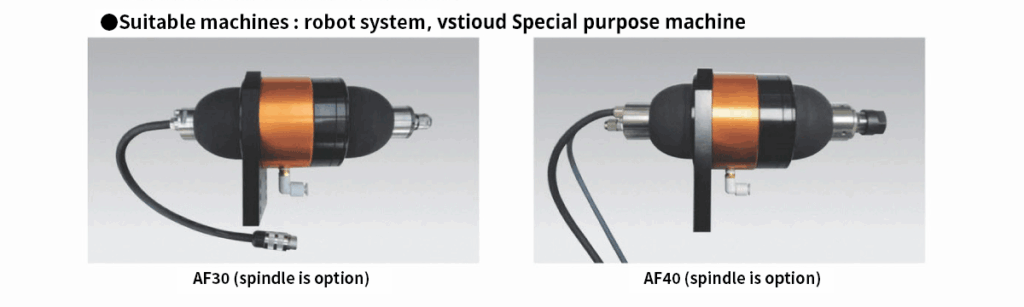

Air Float Deburring Attachment AF30&AF40

Deburring attachment with air float mechanism for automation of deburring process

It’s a deburring attachment with air float design, which enables you to deburr parting line, thick-wall part, gate, ingate, etc…, which exist in your workpiece by one deburring attachment.

Compensation for unmeasured area in X/Y axis direction

Air floating part (motor spindle attachment) can tilt up to 5°and move 360°freely in radial direction at that angle. (Multi-Float function)

Compensation for unmeasured area in Z axis direction

Air floating part can contract 8mm in axial direction. (Axial Float function)

Adjustable floating power to match workpiece material

Adjusting air pressure supplied to air floating part enables free adjustment of floating power (force applied by cutting tool) within air pressure 0.05 – 0.2MPa.

*Please note that floating force may vary depending on posture of cutting tool onto workpiece.

*Automatic adjustment of floating force is possible by using an electro-pneumatic regulator.

Free selection of motor spindle

Air floating deburring attachment is mountable with any motor spindle which you chose and bought in market.

Two sizes available

2 sizes are available. One is AF30 for dia30mm spindle, another is AF40 for dia40mm spindle.

Air float deburring attachment with motor spindle is also available.

We can also offer the attachment which is already assembled on motor spindle (dia30mm or dia40mm).

For details, please contact us.

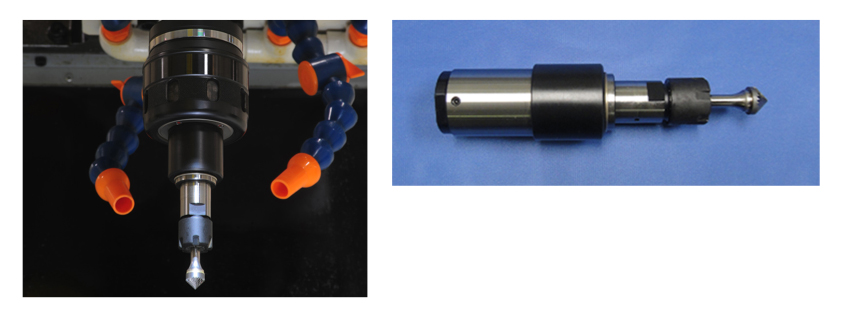

Deburring Tool Holder

Deburring tool holder for machining centers or various special purpose machines

It can remove burrs only without damaging material, by 10mm compressing stroke (C10) or extending stroke (T10) in axial direction, which always enables to maintain optimal pressure of deburring tool against workpiece during deburring process.

3 types of springs with different force are included as standard

3 types of springs with different spring force (for light metal, steel, and hard-to-cut material) are included as standard accessory, so you can easily change springs depending on workpiece material.

Max allowable rotation speed 10,000min-1

A wide variety of machining conditions can be handled. For machining center, please mount it on your milling chuck and use it.

Eligible machine : Machining center, robot system and various special purpose machine

purpose machine